Green Glazed Tiles Adorn Ringling Museum of Art

The Machado Silvetti-designed Center for Asian Art, an addition to the Ringling Museum of Art, is covered in more than 3,000 deep-green, glazed terra cotta tiles that boldy mark the entrance to the grand Florida institution.

Run by Florida State University since 2000, the Ringling Museum of Art is the legacy of John Nicholas Ringling, one of the seven famous Ringling Brothers who shaped modern circuses in the late 19th and early 20th centuries. John was an avid collector of art, and with his wife Mable he built a 56-room, 36,000-square-foot (3,345 m2) Venetian-Gothic mansion, the Ca' d'Zan, in Sarasota. To house the numerous pieces of art amassed through annual trips to Europe, he built a U-shaped "pink palace" that eventually became, with later additions, the Ringling Museum of Art.

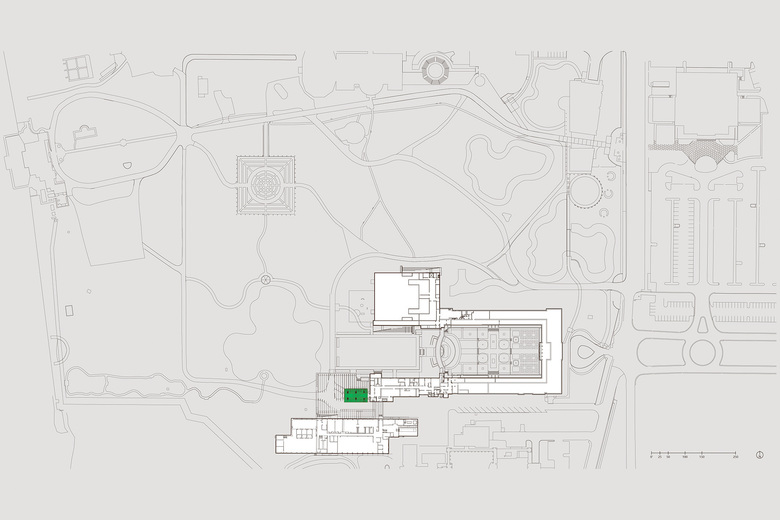

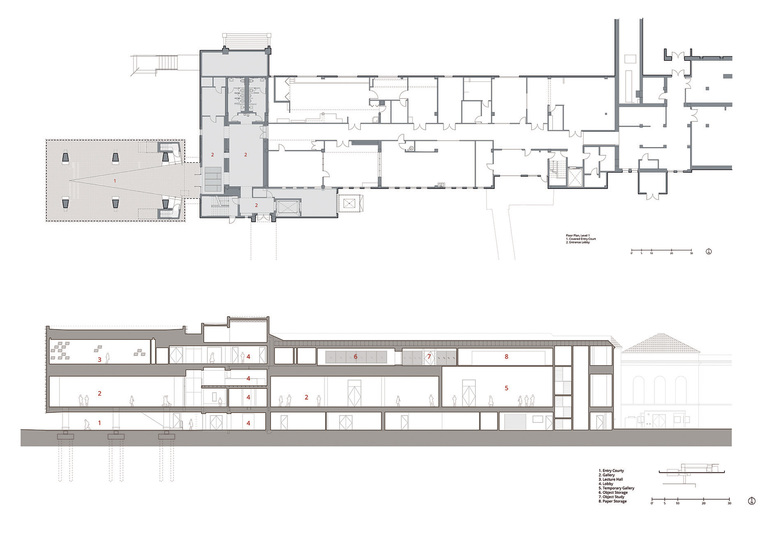

The 7,500-square-foot (700 m2) Center for Asian Art, completed in January 2016, appends itself to the southwest end of the museum complex as part of a project that includes the renovation of 18,000 square feet (1,670 m2) of existing gallery space from temporary exhibition space to permanent galleries for the museum’s growing Asian collection. The three story addition provides a covered entry court at grade, a gallery one floor above, and a lecture hall on the top floor.

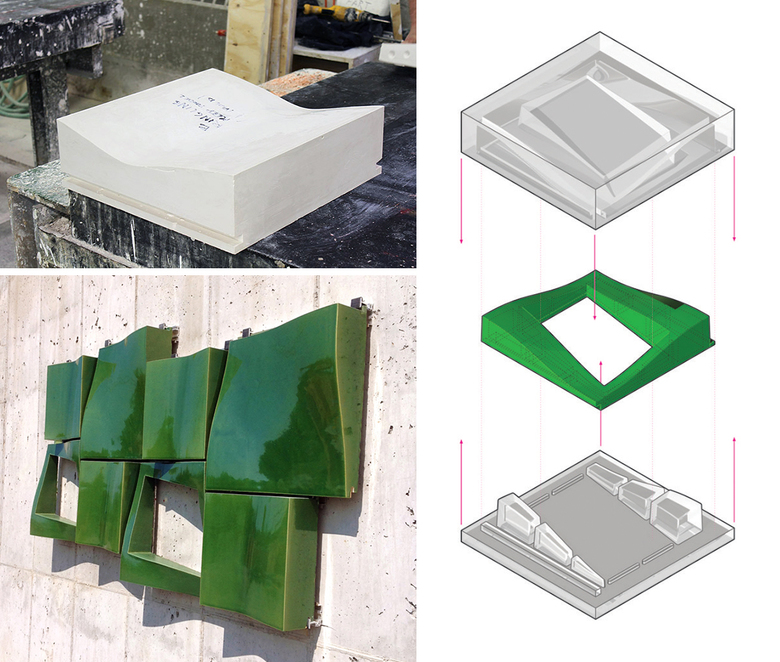

The facade of the Center for Asian Art is composed primarily of two sizes of square, concave tiles (18" and 24" / 45cm and 61cm) that alternate and are mounted at a slight angle to horizontal. Their shapes, placement and orientation create a rippling effect across the facades with diagonal lines visible from certain angles (photo above). Variations on the two main modules happen in two places: at the corners, where smaller, custom pieces give the impression of larger tiles "turning the corner"; and at the small windows that are set into 24" portal pieces in a quasi-checkerboard layout. In all, no more than ten unique shapes were employed.

The more than 3,000 green glazed tiles were produced one at a time by Boston Valley Terra Cotta using three methods: ram-pressed, hand-pressed, and slip-cast. Most of the blocks were made with the first method, where, per Boston Valley, "A clay slug is placed on the [two-part] die and hydraulically pressed into the form. Air forces water in the plaster die to the surface, releasing the piece from the mold." The concave tiles were modeled with Rhino and prototyped with Boston Valley's 5-axis, CNC mill. The tiles weigh approximately 60 to 70 pounds each and were installed on a stainless steel track and clip system.

Ultimately what gives the facade its iridescent appearance is the combination of shape and color. Reportedly architect Rodolfo Machado selected the color after seeing a photo of a man standing in front of a 300-year-old fireplace with a green surround. The final product was glazed with layers of green over layers of gold after months of testing. Since the tiles have a concave shape – a vertical trough on the small tiles and a diagonal trough on the large tiles – the green glaze pooled to the center to give them a variable finish that is as striking as the art inside.

The Center for Asian Art at the Ringling Museum of Art

Client

Florida State University, The John and Mable Ringling Museum of Art

Location

Sarasota, Florida

Architect

Machado Silvetti

Exterior Envelope Consultant

Simpson Gumpertz & Heger, Inc.

Installation Contractor

Sun Tile of Sarasota, Inc

Product

Boston Valley Terra Cotta, TerraClad®

Forming Method

Ram Pressed, Hand Pressed, Slip Cast