US Building of the Week

ONStage at Kaufman Astoria Studios

Home to Sesame Street for decades, Kaufman Astoria Studios is a storied New York City institution that is uniquely integrated into the neighborhood of Astoria, Queens, where it has been located for more than 100 years. Recent developments include an outdoor backlot and the construction of ONStage, which completes the studio's two-block campus. GLUCK+ answered some questions about ONStage.

Location: Astoria, New York, USA

Client: Kaufman Astoria Studios

Architect: GLUCK+

- Design Principal in Charge: Stacie Wong

- Project Team: Jenny Chang, Peter Gluck, James Petty, Olga Reeder, Stacie Wong

Geo-technical and Structural Engineer: McLaren Engineering Group

Support of Excavation: Domani Technical & Design Services / Ancora Engineering

MEP/FP Engineer & Commissioning: GEA Consulting Engineers

Civil & Parking Engineer: Philip Habib & Associates

Acoustics Consultant: Harvey Marshall Berling Associates

Lighting Design Consultant: Lux Populi

Facade Consultant: Forst Consulting and Architecture

Security Consultant: Peace of Mind Technologies

IT/Low Voltage Consultant: Perimeter Watch

Specifications: Construction Specifications

Expeditor: CRS Group/Domani Consulting

Construction Manager: Urban Atelier Group

Owners Advisor: The J Companies

Site Area: 30,926 sf

Building Area: 146,700 sf

See bottom for Important Manufacturers / Products.

We were recommended as a potential architect by the owner’s advisor, who had briefly interacted with us on another project and thought we were smart designers who care about budget and construction. We interviewed with the owner, and although we did not have direct experience in the production studio building type, they felt we were good listeners, would have an open mind and no preconceived notions about the design. We also showed a strong portfolio of projects with big design on streamlined budgets.

Kaufman Astoria Studios (KAS) is the hub of a creative environment, promoting cultural, commercial, entertainment and residential activities that together foster economic growth and a unique community. The new ONStage building completes George Kaufman’s vision for a studio campus, expanding on its rich history in New York City for over 100 years. The remaining underused parcels of land within its campus were zoned for manufacturing, its most recent use as surface parking and a long defunct gas station. This studio development densified the site to its highest and best use, transforming a blight to the neighborhood into a new amenity. The project gives Kaufman Astoria Studios greater connection to the community with frontages both on the campus backlot, which hosts free neighborhood events, as well as along city streets.

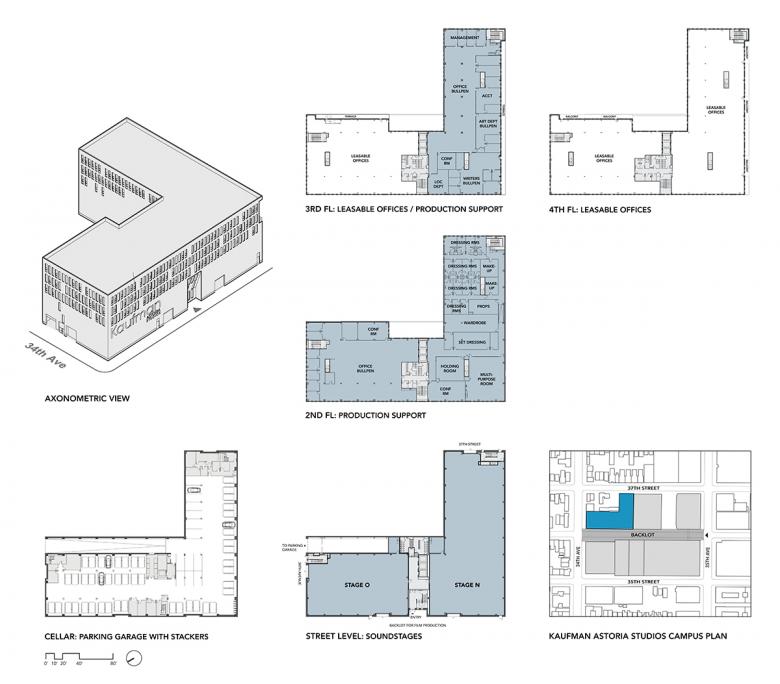

The project entailed a voluntary cleanup of the site approved by the New York State Department of Environmental Conservation to prevent migration of site-related contaminants and protect both the surrounding community and future building occupants from exposure. It transformed a hazardous waste site into a vibrant four-story production hub providing two new film and television production soundstages at the base, production support facilities and leasable office space stacked above, and a parking garage in the cellar to serve the entire campus.

ONStage is located in the dense, urban neighborhood of Astoria, Queens. Unlike most film and TV production studios around the world with land to spread out facilities amongst numerous single-story buildings, building in NYC requires a densely packed strategy to maximize land resources. The design provides a highly marketable building with maximum flexibility and use of space.

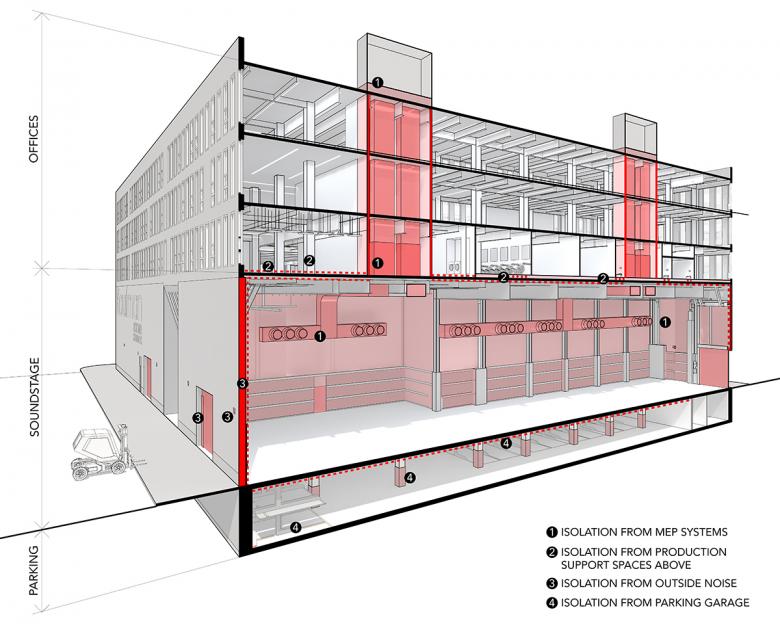

The building is conceived as two stacked programs: 65,000 square feet of commercial office space over 25,000-square-foot production soundstages. Acoustic separation between stage and city, and between stage and spaces above and below, are the most critical technical aspects of the design. The 40-foot tall solid base is a controlled environment using mass to keep sound and light out. The core program are the two soundstages, purposefully designed to be “plugin-ready” with every system and surface intentionally designed to handle any type, size, and style of production. Critical first and foremost is large column-free space. Six foot deep girders were used to achieve a 40 foot high space with 90 foot clear span. The stages are surrounded by 12-inch-thick masonry block walls, faced with insulation and exterior cladding for the facade. Every opening is considered, with the largest openings requiring special purpose soundproof ‘elephant’ doors weighing two tons each, to halt all sound when closed and sealed tight to the building.

The porous top embraces daylight and views with a regularized module of large windows allowing flexible configuration of internal spaces. The modern open office environment provides a mix of private offices and large open bullpen space, 14 foot ceilings with 11 foot high windows for daylight and expansive city views at offices and conference rooms, and outdoor terrace and balcony areas on Levels 3 and 4.

The neighborhood is a mix of manufacturing and residential zoning districts coexisting side-by-side. Urbanistically, the large base is mitigated with a pattern of incisions in the façade that change in prominence during the day based on the angle of the sun. In the evening, illuminated lines embedded in the building’s surface activate and provide safety at the sidewalk. Terraces allow engagement with the local neighborhood as well as production activity on the backlot below, while enjoying panoramic views of the Manhattan skyline. The entrance at the center of building is marked by a simple inflection of facade that leads to the main lobby and a grand staircase connecting the floors.

At the start, we were given a massing and floor plan done by another architect. We reanalyzed the zoning and eliminated front setbacks that impacted the size and marketability of the stages. We also reconfigured the floor plan to centralize the lobby and stair/elevator core, resulting in more marketable tenant spaces and access for both stages to both the city streets as well as the campus backlot.

- A strong thermal envelope with continuous insulation to avoid thermal bridging is critical to meeting stringent energy conservation code. EIFS was used to provide this thermal envelope with thermally broken windows. The design takes advantage of the material’s capacity to be easily carved and incised to give a subtle scale and texture to the large building type.

- Production support spaces benefit from daylight, but privacy and security as well as flexibility to reconfigure interior walls are important. The design incorporated a single size window, vertical almost floor to ceiling, that was replicated and arranged in 2’ increments. This gave the perception of lots of daylight into spaces without complete exposure, and easily allows walls to be added or eliminated without compromising light.

- Daylight and access to outdoor space is a big component of wellness for workspaces. Although the ONStage building is an infill urban building with large expanses of side lot line walls that usually are blank walls devoid of windows, we strategically worked within zoning and code restrictions to inset portions of the side walls to incorporate 2000 square feet of outdoor terraces, balconies and windows, placing them in areas that were not in danger of being covered up by future development of adjacent properties.

- Soundstage Elephant Doors and Acoustic Doors: Clark Doors

- Soundstage Acoustic Surfacing Walls: G&S Acoustics Silent Night panels; Monoglass spray acoustic insulation

- Soundstage Acoustic Surfacing Ceilings: Monoglass spray acoustic insulation

- Floors: Interface Carpet Tile with enhanced back over SCI Tred-MOR carpet cushion; Interface LVT; Euco Diamond Hard exposed concrete floor densifier and sealer

- Exterior: Dryvit EIFS with custom rib pattern

- Windows: Peerless

- Exterior Lighting: Environmental Lights

- Exterior Signage: Signs & Decals

- Lobby Stair: Custom Blackened Steel Stair and Banker Wire Railings

Email interview conducted by John Hill.