US Building of the Week

Omega Yeast

Valerio Dewalt Train

26. 4月 2021

Photo: Tom Harris

Omega Yeast was founded in 2013 to provide freshly made yeast to professional brewers and homebrewers in and beyond its Chicago home. Rapid growth led to the need to expand its facilities, which were designed by Valerio Dewalt Train to fit well into the residential area on the city's Northwest Side. The architects answered a few questions about the recently completed project.

Location: 4720 West Pensacola, Chicago, Illinois, USA

Client: Omega Yeast

Architect: Valerio Dewalt Train

- Design Principal: Christine McGrath Breuer

- Project Managers: Peter Wojtowics, Katie Hart

- Project Team: Zach Reiser

- Interior Designers: Rebecca Snow, Emily Phillips

MEP/FP Engineer: Calor Design Group

Civil Engineer: Terra Engineering

Landscape Architect: Confluence

Lighting Designer: Hugh Lighting Design

Graphic Designer: Knoed Creative

Contractor: J.T. Magen

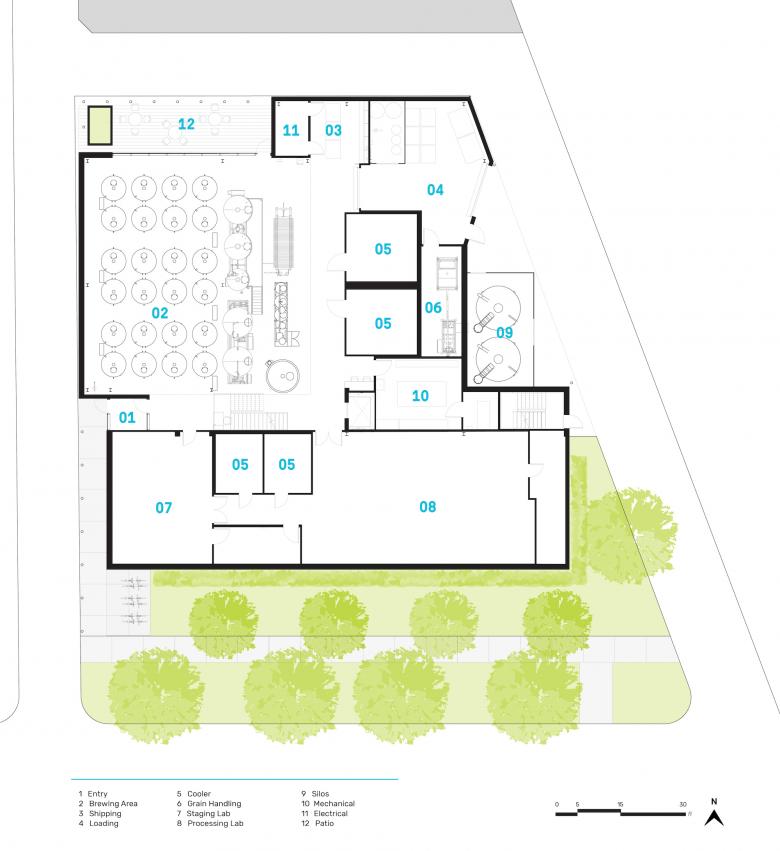

Site Area: 13,742 sf

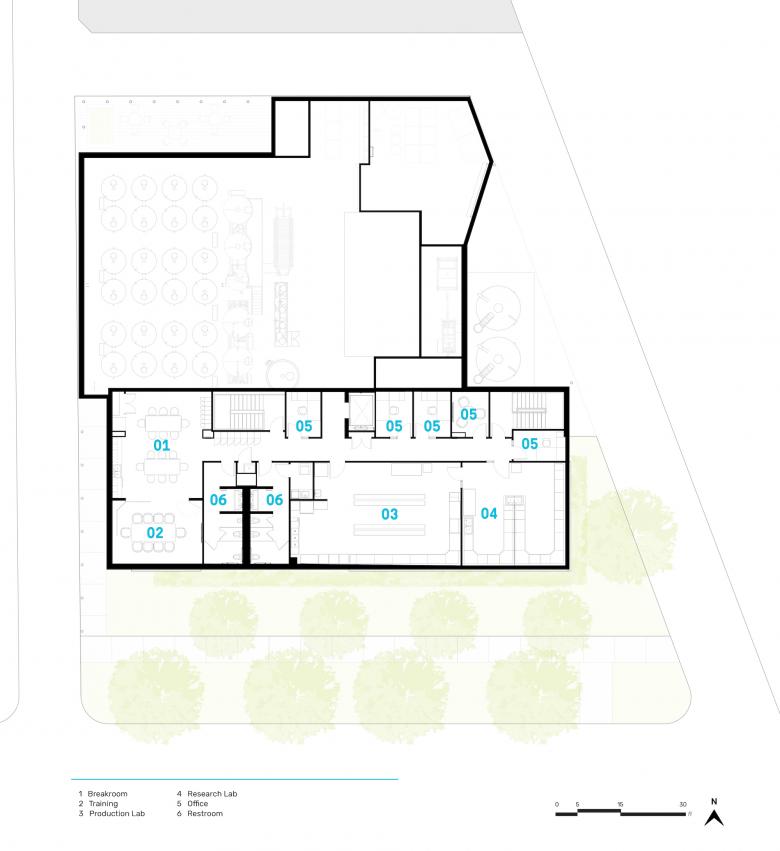

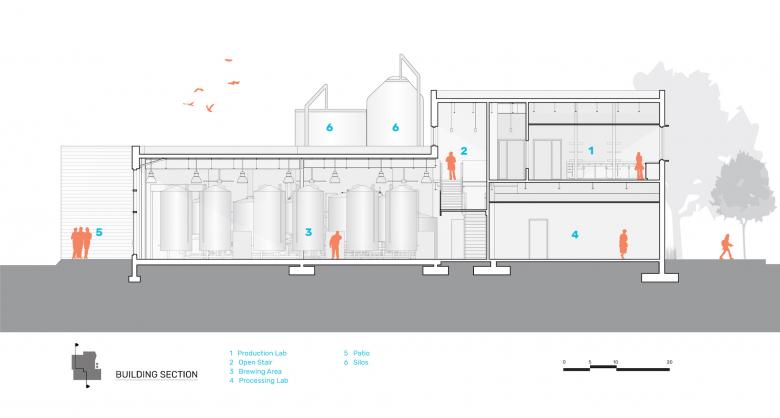

Building Area: 13,800 sf (9,400 sf on 1st floor; 4,300 sf on 2nd floor)

Photo: Tom Harris

What were the circumstances of receiving the commission for this project?Throughout the past decade, the brewing industry has experienced rapid growth, surpassing over 8,000 operating craft breweries in the US alone. As the consumer palette broadened, brewers across the country strived to quench a thirst for unique flavors and creative twists on traditional recipes, using advanced techniques and innovative ingredients. Within this booming industry, the founders of the company had found their niche, with an essential component for the production of craft beer: yeast. Omega Yeast now produces fresh, high quality and pitch-ready liquid yeast for professional brewers and homebrewers.

Photo: Tom Harris

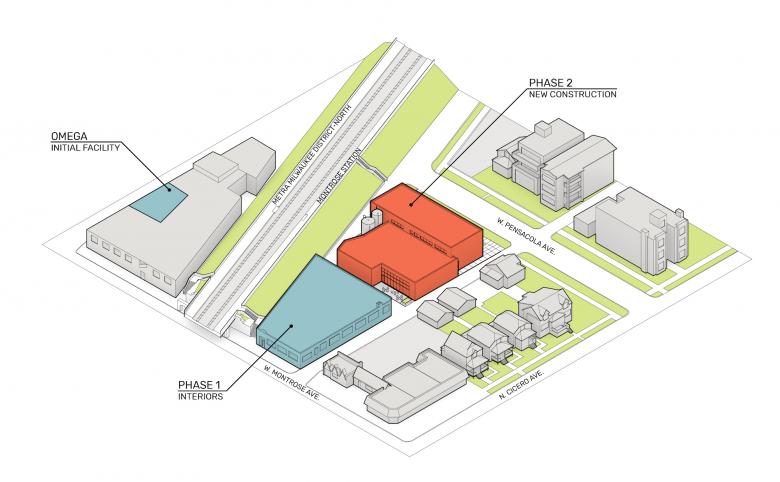

The company started production out of a space within a costume store in Chicago's Portage Park neighborhood, due its advantageous location close to the Metra Commuter Rail, CTA Blue Line, and I-90 expressway. As one of the largest suppliers of brewing yeast in the country, demand quickly outgrew their space, and they purchased an existing building a block over, before realizing that demand was outpacing their renovation. During this renovation, Omega Yeast purchased the lots behind the Phase 1 building to further expand their operations across the alley and to build a new building truly tailored to their unique business. Recognizing that the program was a moving target, designers from Valerio Dewalt Train worked with Omega Yeast to expand their facilities within their recently acquired lots and develop an efficient flow of goods within the building.

Photo: Tom Harris

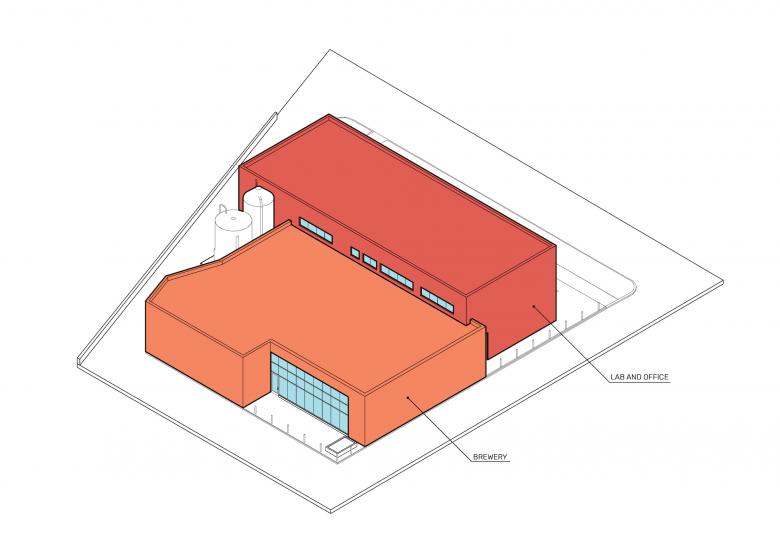

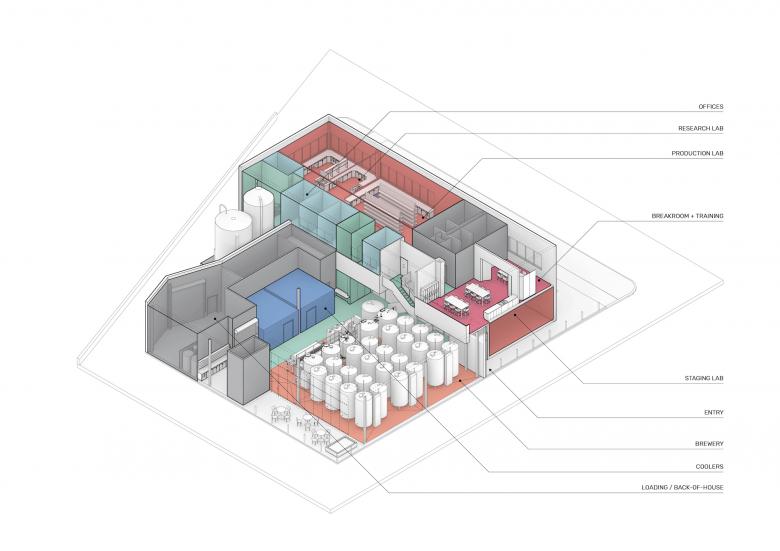

Please provide an overview of the project.As one of the largest supplier of brewer’s yeast in the US, the Omega Yeast production facilities are a quiet yet highly responsive integration to an established Chicago neighborhood. Quietly tucked behind an existing brick building, the adjacent volume is minimally expressed on the street front, using black corrugated metal designed to make the building visually disappear behind landscaping. Wrap-around windows are elevated to face the Metra platform, providing commuters a small glimpse of the science occurring inside. With large scale industrial equipment located by the central alleyway, nation-wide production remains the neighborhood’s best kept secret—silently visible through a large curtain wall for those that know where to find it.

Photo: Tom Harris

How does the design respond to the unique qualities of the site and existing building?The building’s design is a direct response to its site and its program. Located within a residential area, it was important to Omega Yeast that they remain good neighbors, especially since their business also catered to local clientele. To achieve this, the loud production facilities were pushed to the back of the building, towards their existing facility and Metra Commuter Rail, leaving the quieter lab spaces, offices and the break room toward the residential street front. Designers took cues from the company’s recent rebrand, adopting its colors with white brick, black and white corrugated metal, warm wood finishes, and “Omega Yeast Blue” branding accents. Facing the neighborhood, the volume is minimally expressed, using black corrugated metal designed to make the building visually disappear behind landscaping on the street front.

Photo: Tom Harris

The building is highly responsive to the Metra on the east side of the lot. The lab spaces on the second floor have wrap-around windows, elevated to face the platform, revealing a small glimpse of the science behind the yeast to passing commuters. Adjacent to the eastern wall are large silos for spent grain and dry grain, one of which is painted in brand colors with the logo to attract attention. By the alley on the north side, a small patio faces a large glazed opening that dramatically exposes the brewing facilities. Because it is mainly visible from the platform and alley, the patio is an open invitation to friends of Omega that see their colleagues and drop by for a drink.

Photo: Tom Harris

How did the project change between the initial design stage and its completion?As the design team began to develop the building, Omega Yeast found itself struggling to meet demand throughout the process, and needed to expand. Plans were quickly altered as new and larger equipment was installed in the main brewery to meet their production needs.

Photo: Tom Harris

What products or materials have contributed to the success of the completed project?The volume facing the residential neighborhood used black corrugated metal panel by Pac-Clad. This matte-finish material and dark color helped achieve a discrete look, to draw less attention among neighboring residential houses.

Email interview conducted by John Hill.

Photo: Tom Harris

Important Manufacturers / Products:

Exterior Cladding Materials:

- Corrugated Metal Panel (Pac-Clad)

- Brick (Palmetto)

- Aluminum Siding (Dizal)

Brewery:

- Flooring - Argelith, Fully Vitrified Tile / BASF; Traffic Coating / Stonhard, Stonclad

- Stair - Custom, Garbe Iron Works & McNichols

Breakroom:

- Millwork (Sliding Wall) - Custom, Icon Modern

- Millwork (Cabinets) - Custom, Herner Geissler

- Millwork (Countertop) - Caeserstone

- Millwork (Laminate) - Formica & Abet Laminati

- Wall Tile - Arizona Tile

- Floor Tile - Crossville, Nest

Labs:

- Millwork (Countertop) - Caeserstone & Durcon, Epoxy Resin

- Millwork (Cabinets) - Custom, Laboratory Design & Supply and Herner Geissler

- Millwork (Shelving) - Formica